DO-160 Salt Atmosphere Test (Section 14) and Test Devices

What is the DO-160 Salt Atmosphere Test?

The DO-160 standard was developed to assess the environmental resilience of aviation electronics and components that may face environmental challenges during flight. Section 14 of this standard is called the Salt Atmosphere (Corrosion) Test, which tests the durability of aircraft components in salty water and humid environments.

This test is conducted to determine how resistant aviation electronics, especially those used in marine aircraft, coastal aircraft, and military aircraft, are to corrosion and oxidation effects in high-humidity environments or at sea level. It is a critical test for ensuring the durability of such components in challenging conditions.

Salt Atmosphere Test in the DO-160 Standard

DO-160 Section 14 is also related to the following standards:

- IEC 60068-2-11 (Salt Spray Test)

- MIL-STD-810H Method 509.7 (Salt Atmosphere and Corrosion Test)

- RTCA/DO-160G Section 14.0 (Salt Atmosphere and Corrosion Resistance Test)

This test is applied to assess how devices respond and withstand exposure to seawater vapor and saline environments.

Test Purpose

The Salt Atmosphere Test is carried out to measure the long-term durability of devices exposed to seawater vapor, salt moisture, and corrosion during flight. The test evaluates the surface oxidation of electronic components, corrosion of electrical connections, rusting of mechanical parts, and material degradation.

How is the DO-160 Salt Atmosphere Test Conducted?

The Salt Atmosphere Test is conducted in the following stages:

- Preparation: The device to be tested is placed in a specially designed salt spray test chamber.

- Application of Salt Water Vapor: A 5% sodium chloride (NaCl) solution is sprayed into the chamber to create a salt atmosphere.

- Temperature and Humidity Control: The temperature inside the chamber is controlled between 35°C and 50°C throughout the test.

- Test Duration: The test duration can range from 24 to 96 hours, during which corrosion formation is monitored.

- Function Control: After the test, the mechanical, electronic, and chemical durability of the device is evaluated.

Devices Used for the Salt Atmosphere Test

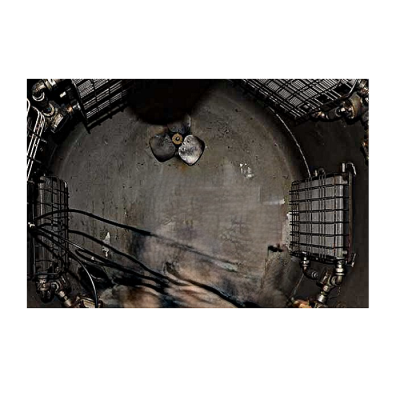

The DO-160 Section 14 Salt Atmosphere Test is performed using salt spray cabinets and corrosion test chambers. These test devices are designed to measure how aviation electronics respond to salt moisture and corrosion effects.

- Salt Spray Test Chambers

- Can perform continuous or intermittent spraying with a 5% NaCl solution.

- Provides temperature control between 35°C and 50°C.

- Allows adjustment of salt vapor density and spray rate.

- Provides the ability to observe corrosion formation on the surface of the sample during the test.

- Corrosion Test Chambers

- Simulates high-humidity and salt-laden atmospheric conditions.

- Can test corrosion resistance for various types of materials.

- Includes precise temperature and humidity control systems.

- Offers programmable cycles for long-term tests.

Applications of the Test

The DO-160 Salt Atmosphere Test is applied in the following areas:

- Marine aircraft and components used in coastal regions

- Military aviation and defense electronics

- Radar and communication equipment

- Electrical connections, cable harnesses, and connectors

- Aerospace materials and exterior components

Results of the DO-160 Salt Atmosphere Test

The results of the test analyze the device’s resistance to corrosion in a salt environment, the rate of surface rusting, electrical performance degradation, and post-test functionality. Devices that pass the test demonstrate their ability to operate safely in marine environments.

Conclusion

The DO-160 Section 14 Salt Atmosphere Test is a critical test that evaluates the durability of aviation electronics against salt and humid environments. It is of great importance, especially for marine aircraft and military aircraft. The salt spray cabinets and corrosion test chambers used in the test provide realistic conditions, ensuring the long life of aerospace components.

You can contact us for more detailed information on the DO-160 Salt Atmosphere Test (Section 14) and Test Devices and to place an order in custom sizes according to your needs.